2025

Spring

Soft and round on the palate, with bittersweet cocoa and black cherry tasting notes. This coffee was medium-bodied with loads of natural sweetness. A crowd pleaser.

Summer

A light and crisp Red Bourbon from the Shangi Hills washing station in Rwanda. We tasted black tea and lemon zest. The Shangi Hills was excellent as an iced coffee.

Summer

This coffee was truly wild. On the nose, it smelled like fresh cut peaches. However, in the cup, we tasted Bubble Gum, Strawberry Taffy, & Mango. A true standout coffee!

2024

Winter

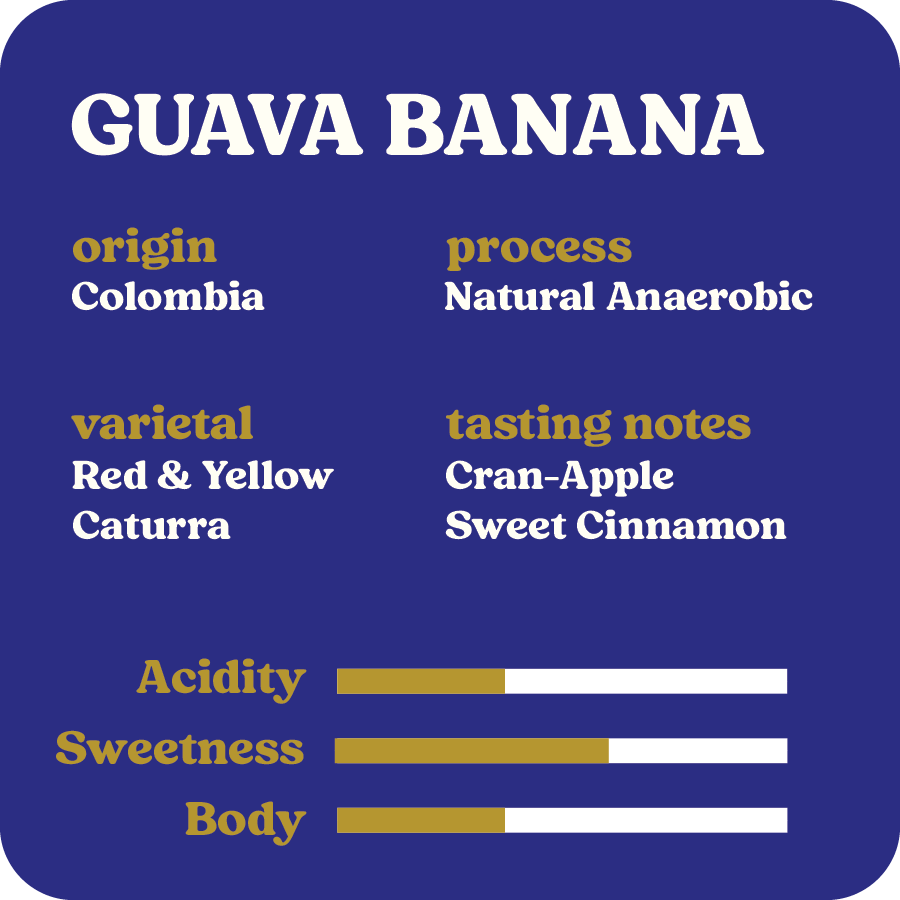

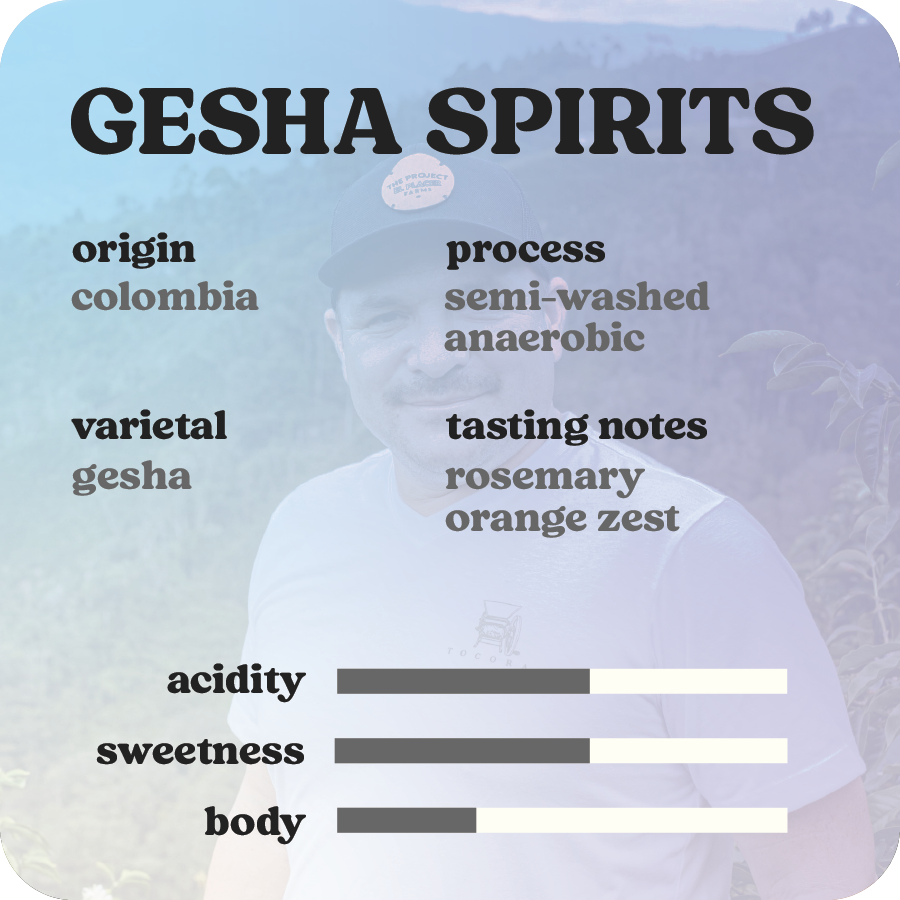

From mastermind Jorge Elías Rojas in Tolima, Colombia, this coffee underwent a process that Jorge calls "Pink Joy". This involves a 96-hour anaerobic fermentation, followed by a 15-day sun drying session.

Spring

From El Vergel Estate in Tolima, Colombia. This coffee underwent an 84-hour fermentation in steel tanks with added lixiviates, a coffee by-product containing a microbial population. Imported by our friends at Forest Coffee.

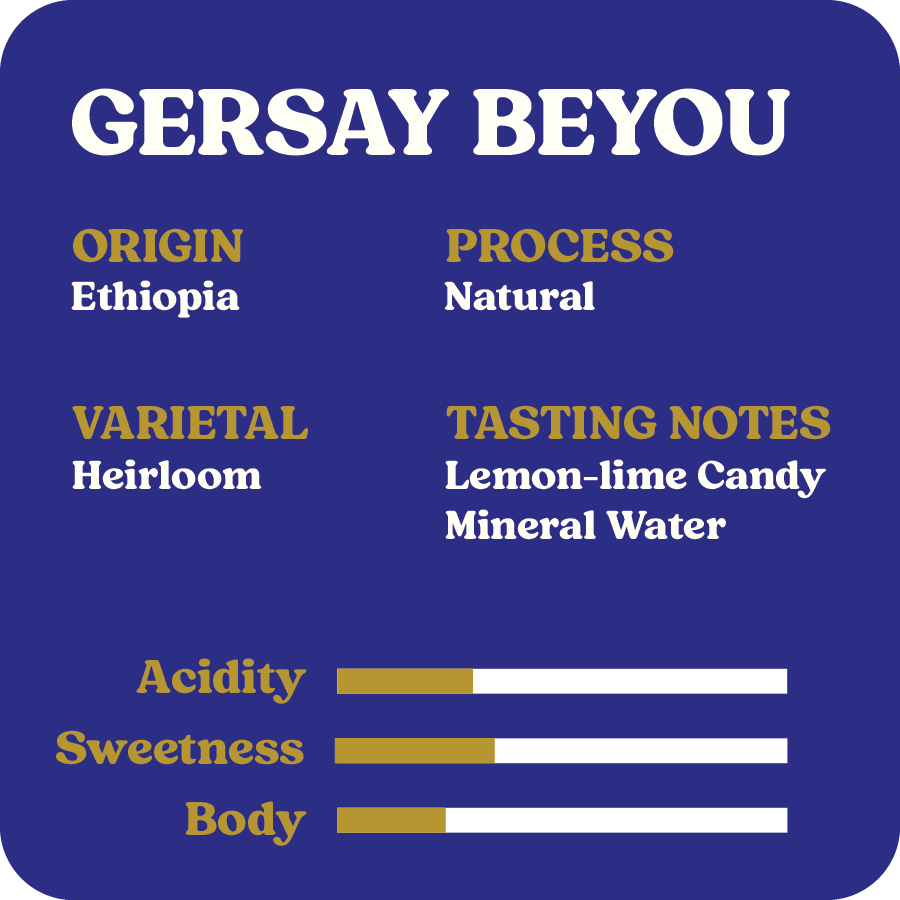

Spring

This was a spectacularly light and crisp natural Ethiopian. Intense citrusy notes, it reminded us of lemon-lime soda with a notable effervescence. This coffee was imported by our friends at Coffee Quest.

Summer

Imported by our friends at Balzac Brothers, this coffee hailed from Aquiares in the Turrialba region of Costa Rica. We were amazed by how fragrant this coffee was during grinding. Notes of strawberry jam and sparkling lime soda highlighted the cup.

Summer-Fall

We were searching for a classic, well-rounded coffee to use on iced coffee in our shops, and this coffee fit the bill beautifully. Nutty, silky, with natural sweetness and a dried raisin flavor profile. An excellent washed coffee from an up-and-coming producer, German Carranza.

Fall

From our favorite producers, Elias and Shady Batter, the Pink Borbon Punch underwent a 12-hour oxidation process, followed by a 24-hour anaerobic fermentation. Naturally sweet and packed with rhubarb and strawberry notes!

Fall

An El Vergel Estate coffee we've gone back to numerous times. For this harvest, Elias & Shady processed the coffee in a controlled anaerobic environment for 48-60 hours. Imported by our friends at Forest Green Coffee.

Fall

From famed Wilder Lazo, this coffee underwent a double-fermentation, immersed in anaerobic mucilage, for 140 hours! After this, it was laid out to sun-dry with tangerine peels for added complexity. Super zesty and floral.

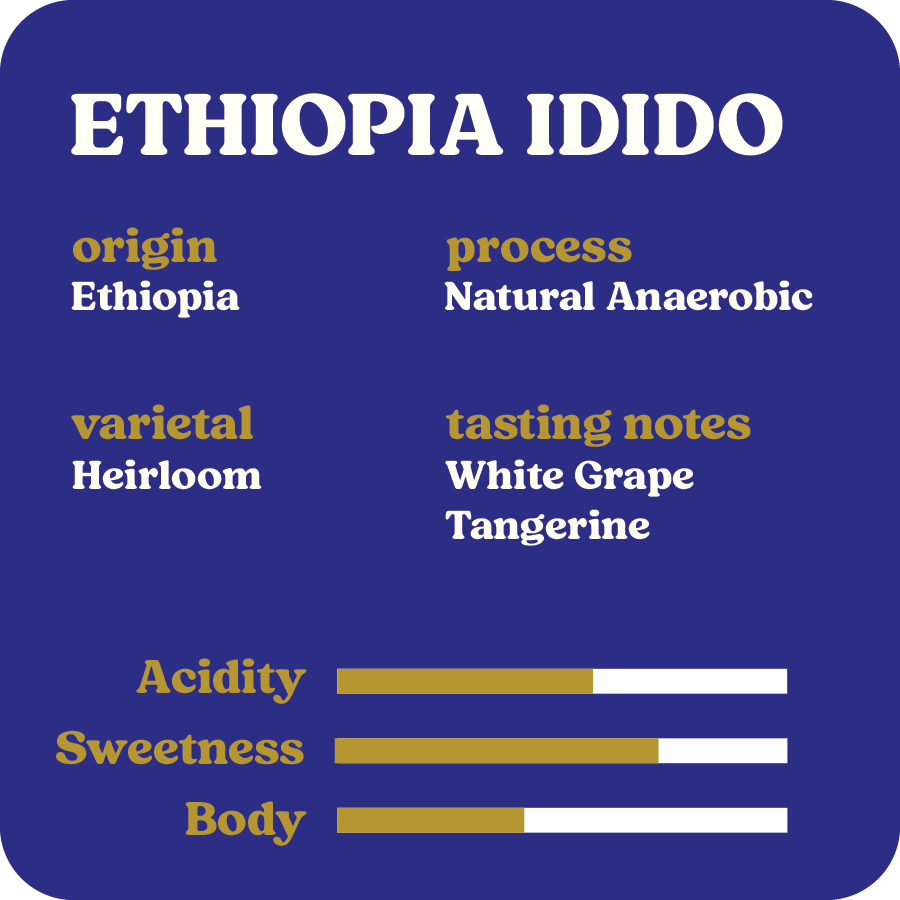

Fall

A coffee from the Yismashewa Washing Station in Gedeo, Ethiopia. Reminiscent of the berry, fruity-forward natural Ethiopians of old, except this coffee was bursting with citrusy tangerine. We mostly brewed this coffee on drip in our shops.